Protecting Sensitive Electronics from Interference

Designed to ensure maximum equipment uptime and functionality

EMI Shielding for Sensitive Electronics

Protecting Sensitive Electronics

In sensitive electronics, EMI (electromagnetic interference) or RFI (radio frequency interference) can cause service problems ranging from relatively minor power disruptions to outright system failure. Telecom/Datacom, military and medical industries are typically most susceptible to EMI interruptions due to large amounts of high-frequency equipment being housed in small spaces.

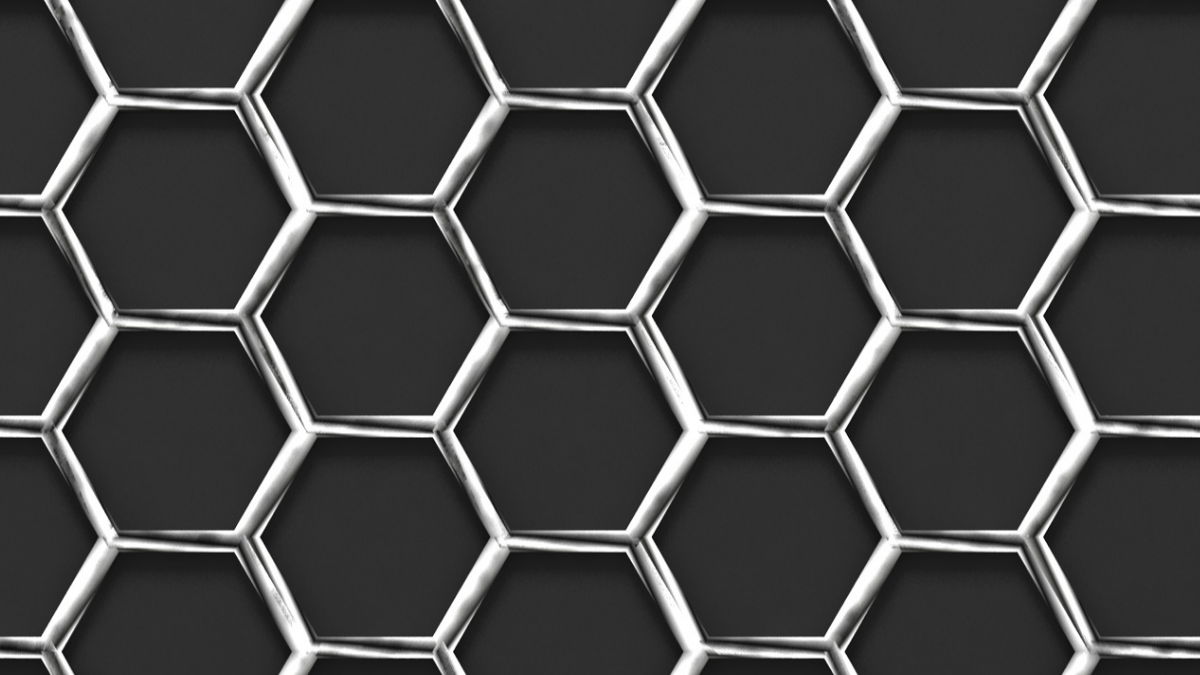

Solving for EMI on its own is simple: fully enclose the electronics. The challenge emerges when you must incorporate an opening in a cabinet: passive or active cooling solutions, enclosure access, etc. UAF specializes in custom designed EMI shielding vent solutions for your indoor and outdoor equipment. Whether you need to add a simple honeycomb vent panel or a complex Dual EMI solution that protects equipment from the effects of both EMI and particulate, our engineers can find a solution that meets your needs.

How UAF EMI Shielding Works

There are three core objectives to UAF’s approach to integrating EMI shielding into our filters:

- EMI/RFI shielding with positive grounding

- Air straightening for maximum cooling efficiency

- High dust arrestance with low pressure drop

EMI/RFI shielding begins with our single or dual-honeycomb filter structure which creates cells designed to deflect and absorb EMI “noise”. The honeycomb pattern has the added effect of essentially “straightening” the airflow allowing for even distribution and minimal impedance, providing better cooling of the system by creating a more efficient, laminar air flow. The addition of a stainless screen can act as an equalizer to the velocity profile of the air after it exits the honeycomb to make the flow more uniform.

Edge-to-edge venting combined with precision-fabricated frames and housing enables that most sought-after combination of high dust arrestance and low pressure drop.

EMI Vent Panels vs. UAF Dual EMI Shielding

EMI vent panels are designed for the reduction of electromagnetic interference only, using a honeycomb or stainless steel mesh. EMI vent panels are essentially a permanent solution and have almost no pressure drop because the honeycomb is 97% open cells and there is no additional media adding resistance to the panel. UAF can keep these simple, or design a vent panel that is more complex, with offset layers of honeycomb for better EMI attenuation.

Dual EMI vent panels incorporate air filtration into the EMI vent panel: our Quadrafoam filter media and honeycomb are included in one package. If an application requires filtration in addition to EMI reduction, a dual EMI vent panel is typically used on the intake to protect electronics from dust and other damaging hazards as air is pulled into the equipment/cabinet and an EMI vent panel (honeycomb only) is used on the exhaust side.

In addition to standard EMI vent panels and dual EMI solutions, UAF specializes in custom solutions that can meet almost any non-standard design specification — radial-shaped filters for MRI machines, and heavy duty options designed for ruggedized military communications equipment, and small/unique profiles used in telecommunications and data center switches and routers are just a few examples.

Partnering with UAF

Typically, engineers first come to UAF for an EMI solution and then realize over the course of the project that they require filtration as well. Generally, we’re able to introduce the “two birds, one stone” approach early enough into the process so that engineers are able to move through their projects more efficiently and without delays. UAF’s engineering team are holistic partners in understanding our customers’ needs and bringing their expertise to the customer design. Think you have a unique issue? Try us- we’ve likely solved your protection challenge before!

Our engineers also work closely with the UAF production team to understand how design decisions will impact your end product’s cost and lead time, allowing you to make informed trade-offs to meet your budget or timeline requirements. UAF can also provide quick turn prototypes for most application for form, fit, and function testing.

Built to US and International Standards

UAF EMI shielding filters are built to meet the requirements of CE, Telcordia NEBS and UL. Dual EMI filters use our flame retardant Quadrafoam media that offers unusually high dust arrestance at minimal resistance. All dual EMI filters are removable, cleanable, washable and provide effective shielding up to 10 GHz. UAF also offers a RoHS-compliant corrosion resistant finish that meets MIL-DTL-5541 Class 1A or Class 3 on all aluminum parts. While the corrosion resistant finish does not improve EMI attenuation, it prevents the material from corroding which ultimately improves EMI shielding effectiveness. Additionally, UAF offers value-add enhancements including metalized fabric over foam EMI gaskets and spring clips to improve grounding between vent panel and enclosures.