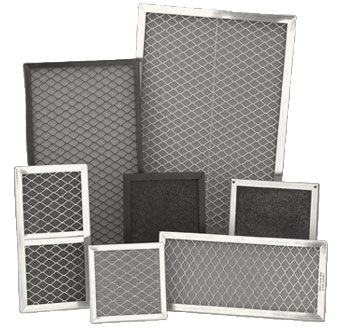

Uni-Foam Air Filters | Universal Air Filter

High dust arrestance, low pressure drop washable media

Uni-Foam fan air filters are designed to provide high dust arrestance where a permanent, cleanable filter is required in medical equipment, electronics, computer, telecom, datacom and general purpose equipment. Uni-foam media can be used in a wide variety of indoor and outdoor applications.

The foam media can withstand exposure to moisture, if installed in outdoor environments. The cellular media structure acts as a mist eliminator to reduce water ingress caused by rainfall or water splash. Certain Uni-Foam air filter models are specifically designed for use in “limited-space” equipment.

Applications

Each uni-foam air filter model performs with a high degree of dust arrestance when installed in medical, electronics and computer equipment where permanent type, cleanable filters are required. FF-2X, FF-3, FF-5, FF-5X filters have been specially designed for equipment where space is limited. Order an air filter prototype for your application today.

Filtration Performance Data: