IP-Rated Air Filters

IP-Rated Air Filters

Electronics enclosures deployed in demanding environments require precise protection against dust, water, and airborne contaminants. Universal Air Filter designs custom air filtration solutions that help OEMs achieve their target IP (Ingress Protection) ratings while maintaining optimal airflow for thermal management.

Since 1959, we’ve partnered with engineers across telecommunications, industrial controls, EV charging, and outdoor electronics to deliver certification-ready filters with 48-hour prototyping and in-house engineering support.

Important: IP ratings are enclosure-level certifications dependent on overall enclosure design, including gaskets, seals, louvers, and housing construction. Air filters alone cannot be IP-rated, but the right filter is critical to achieving your enclosure’s target protection level. Our engineers work with your team to optimize the complete filtration system.

Dust Protection Filters: IP4X, IP5X, and IP6X

Dust protection is essential for electronics operating in industrial facilities, outdoor installations, construction sites, and anywhere airborne particulates threaten sensitive components. UAF offers multiple filter solutions engineered to support dust protection requirements from basic particulate blocking to complete dust-tight sealing.

IP4X Filters: Protection Against Objects Greater Than 1mm

IP4X protection prevents entry of solid objects larger than 1mm, including wires, large particulates, and insects. This baseline level of dust protection suits indoor installations with controlled environments where fine dust is not a primary concern.

UAF Products with IP4X Capability:

- Quadrafoam™

- Unifoam

- Polyester

- Electrostatic

- Hydrophobic

- Metal Mesh

- High Efficiency

- FaraVent™ Duo

- PentaVent™

IP5X Filters: Dust Protected

IP5X represents the threshold for true dust protection. While some dust may enter the enclosure, the quantity will not interfere with equipment operation. This rating suits most industrial and commercial applications where equipment must operate reliably in dusty conditions without requiring complete sealing.

UAF Products with IP5X Capability:

- Quadrafoam™

- High Efficiency

- FaraVent™ Duo

- PentaVent™

- Weather Resistant

IP6X Filters: Dust Tight

IP6X is the highest level of dust protection, requiring complete sealing against dust ingress even under vacuum conditions for up to eight hours. This rating is essential for equipment deployed in extremely dusty environments like construction sites, agricultural facilities, desert installations, and mining operations.

UAF Products with IP6X Capability:

- OSP

Water Protection Filters: IPX4 and IPX5

Outdoor electronics, weather-exposed equipment, and enclosures subject to washdown require filtration that prevents water ingress while maintaining airflow. UAF’s water-resistant filter solutions use hydrophobic media, specialized constructions, and ruggedized designs to protect against splash, spray, and pressurized water.

IPX4 Filters: Splash Resistant

IPX4 protection guards against water splashed from any direction, making it suitable for outdoor enclosures, rain-exposed installations, and equipment subject to occasional water contact. This rating represents the minimum water protection for most outdoor applications.

UAF Products with IPX4 Capability:

- Hydrophobic

- PentaVent™

IPX5 Filters: Low-Pressure Water Jets

IPX5 protection withstands water jets from any direction, equivalent to a garden hose spray or heavy rain driven by wind. This rating is required for equipment subject to direct water exposure, cleaning procedures, or deployment in severe weather conditions.

UAF Products with IPX5 Capability:

- Hydrophobic

- Weather Resistant

- OSP

Combined IP Rating Solutions

Real-world applications typically require protection against both dust and water. Common combined ratings include IP54 (dust protected, splash resistant), IP55 (dust protected, water jets), and IP65 (dust tight, water jets). UAF engineers help you select and configure filters that support your complete IP rating requirements.

IP54: Dust Protected + Splash Resistant

IP54 is widely specified for outdoor cabinets, industrial controls, and equipment in semi-sheltered locations. Based on the product capabilities matrix, PentaVent™ is the only filter with both IP5X and IPX4 capabilities.

IP55: Dust Protected + Water Jets

IP55 provides enhanced water protection for equipment subject to direct water spray or hose-down cleaning. Based on the product capabilities matrix, Weather Resistant filters have both IP5X and IPX5 capabilities.

IP65: Dust Tight + Water Jets

IP65 represents the highest commonly specified combined rating for ventilated enclosures, requiring complete dust sealing plus water jet resistance. Based on the product capabilities matrix, OSP filters have both IP6X and IPX5 capabilities. Achieving IP65 with a ventilated enclosure demands careful attention to filter selection, sealing, and overall enclosure design. Our engineering team collaborates with customers to optimize the complete system.

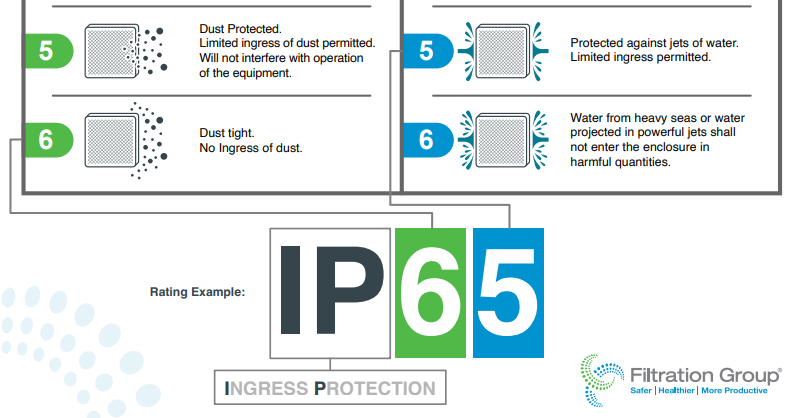

Understanding IP Ratings for Air Filtration

The IP (Ingress Protection) rating system, defined by IEC 60529, classifies the degree of protection an enclosure provides against solid objects and liquids. Every IP rating consists of two digits: the first indicates protection against solids (dust and debris), while the second indicates protection against water.

When designing ventilated enclosures that require airflow for cooling, the air filter becomes one of the most critical components in achieving your target IP rating. The filter must balance contamination protection with sufficient airflow to prevent equipment overheating.

UAF Product IP Rating Capabilities

| Product | IP4X | IP5X | IP6X | IPX4 | IPX5 |

|---|---|---|---|---|---|

| Quadrafoam™ | ✓ | ✓ | |||

| Unifoam | ✓ | ||||

| Polyester | ✓ | ||||

| Electrostatic | ✓ | ||||

| Hydrophobic | ✓ | ✓ | ✓ | ||

| Metal Mesh | ✓ | ||||

| High Efficiency | ✓ | ✓ | |||

| FaraVent™ | |||||

| FaraVent™ Duo | ✓ | ✓ | |||

| PentaVent™ | ✓ | ✓ | ✓ | ||

| Weather Resistant | ✓ | ✓ | |||

| OSP | ✓ | ✓ |

Note: IP ratings are enclosure-level certifications. Filter capabilities support achieving these ratings when combined with proper enclosure design.

How IP Ratings Work

First Digit: Solids Protection (0-6)

| Rating | Protection Level |

|---|---|

| 1 | Protected against solid objects greater than 50mm, such as a hand |

| 2 | Protected against solid objects greater than 12.5mm, such as a finger |

| 3 | Protected against solid objects greater than 12.5mm, such as a screwdriver |

| 4 | Protected against solid objects greater than 1mm, such as large particulates or a wire |

| 5 | Dust protected. Limited ingress of dust permitted. Will not interfere with operation of the equipment. |

| 6 | Dust protected. Limited ingress of dust permitted. Will not interfere with the operation of the equipment. |

Second Digit: Water Protection (0-6)

| Rating | Protection Level |

|---|---|

| 1 | Protected against vertically falling drops of water. Limited ingress permitted. |

| 2 | Protected against vertically falling drops of water with enclosure tilted up to 15 degrees from the vertical. Limited ingress permitted. |

| 3 | Protected against sprays of water up to 60 degrees from the vertical. Limited ingress permitted for three minutes. |

| 4 | Protected against water splashed from all directions. Limited ingress permitted. |

| 5 | Protected against jets of water. Limited ingress permitted. |

| 6 | Water from heavy seas or water projected in powerful jets shall not enter the enclosure in harmful quantities. |

What Does “X” Mean?

When you see ratings like IP5X or IPX4, the “X” indicates that the enclosure was not tested for that particular type of protection.

- IP5X means dust protected, but not tested for water ingress.

- IPX4 means splash resistant, but not tested for dust protection.

Why Filters Alone Do Not Determine IP Ratings

IP ratings are enclosure-level certifications, not component-level specifications. While the air filter is critical to achieving your target rating, multiple factors influence the final result:

- Enclosure design: Housing materials, joints, and construction quality

- Gaskets and seals: Door gaskets, cable entry seals, and filter mounting seals

- Louvers and hoods: Mechanical protection that works with filters to block water and debris

- Air intake design: Labyrinth paths, snorkels, and baffles that enhance protection

UAF engineers understand these system-level considerations and work with your team to optimize the complete filtration solution. We provide guidance on filter selection, mounting methods, sealing approaches, and design modifications that contribute to achieving your target IP rating.

Industries Requiring IP-Rated Filtration

Telecommunications

Outdoor telecom cabinets, cell tower equipment, and network infrastructure require IP-rated protection against environmental contaminants. UAF filters meet NEBS GR-487 requirements for outside plant equipment and support IP54/IP55 ratings common in telecom deployments.

EV Charging

Electric vehicle charging stations face dust, rain, snow, and temperature extremes. PentaVent™ filters help charging equipment meet IP44/NEMA 3R requirements specified by NEVI (National Electric Vehicle Infrastructure) standards without bulky louvers or shields.

Industrial Automation

Factory automation equipment, process controls, and industrial machinery operate in dusty, sometimes wet environments. Our filters support IP54 through IP65 ratings while providing the airflow needed for reliable thermal management.

Outdoor Electronics

Digital signage, kiosks, traffic controls, and IoT devices deployed outdoors require robust environmental protection. OSP and Weather Resistant filters protect against wind-driven rain, humidity, and airborne debris.

Power Generation

Power electronics, inverters, and switchgear require dust and water protection while dissipating significant heat. Our high-efficiency and hydrophobic filter solutions balance protection with airflow requirements.

Military and Defense

Ruggedized electronics must operate in extreme environments, from desert dust to maritime salt spray. UAF filters meet MIL-STD requirements and support the demanding IP ratings specified for defense applications.

Certifications and Compliance

UAF filters complement IP rating requirements with certifications that address fire safety, environmental compliance, and industry-specific standards:

- UL 900: Air filter units rated for flammability and smoke-developed characteristics

- UL 94 HF-1: Horizontal flame test compliance for filter media

- NEBS GR-63-CORE / GR-78-CORE: Network Equipment-Building System requirements for telecom

- NEBS GR-487-CORE: Outside plant equipment environmental requirements

- MIL-STD: Military standard compliance for defense applications

- RoHS / REACH: Environmental compliance for hazardous substance restrictions

Start Your IP-Rated Filter Project

Universal Air Filter’s engineering team is ready to help you select and design filtration solutions that support your target IP rating. With 48-hour prototyping, in-house engineering collaboration, and over 65 years of application expertise, we accelerate your product development while ensuring certification-ready performance.