Protecting Equipment from Corrosion

The Crucial Role of Custom Air Filters in Combating Corrosion in Electronic Equipment

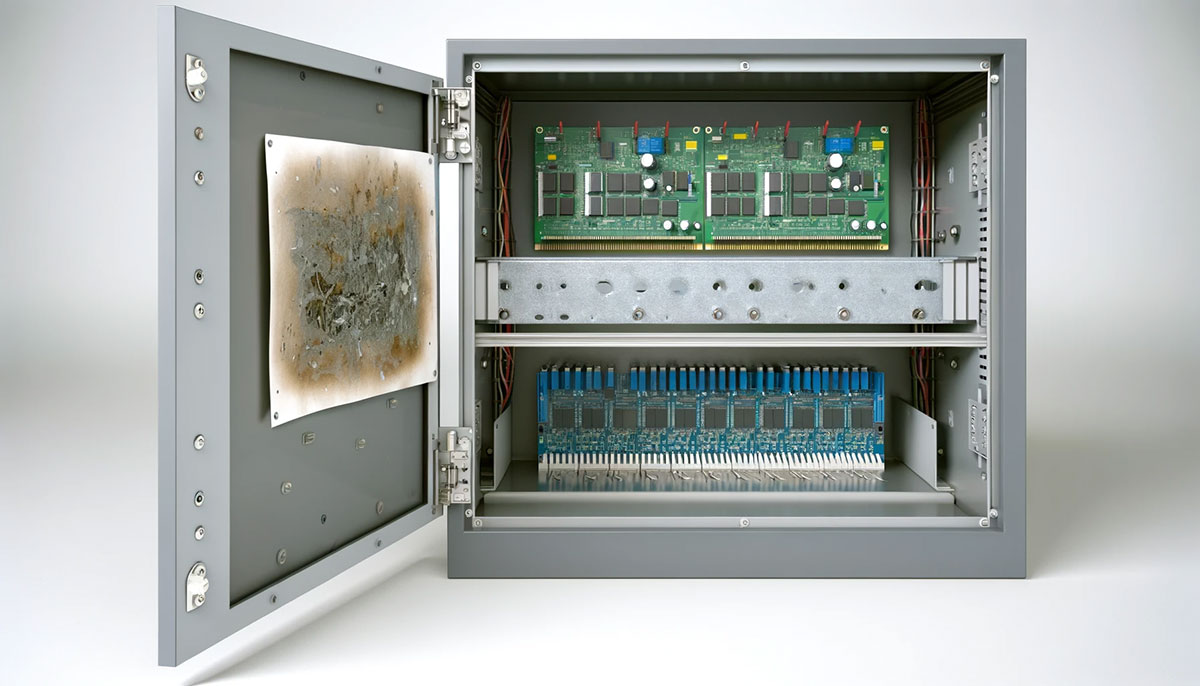

In the intricate world of electronic equipment, corrosion emerges as a silent yet formidable adversary. This pervasive issue not only undermines the reliability and longevity of devices but also poses significant operational risks. Amid various strategies to combat electronic corrosion, one often overlooked hero stands out: custom air filters.

Understanding Corrosion in Electronics

Corrosion in electronic equipment is primarily a chemical reaction between the metal components within devices and corrosive agents present in their operating environments. This reaction can lead to the deterioration of metal parts, loss of electrical conductivity, and ultimately, the failure of electronic systems. The consequences range from minor disruptions in functionality to catastrophic system failures, potentially incurring significant financial and operational costs.

High-Risk Environments for Electronic Corrosion

Electronics housed in industrial settings, coastal areas, or regions with high pollution levels are particularly vulnerable to corrosion. Industrial environments often contain a mix of corrosive gases, such as sulfur dioxide (SO2) and nitrogen oxides (NOx), which can accelerate metal deterioration. Coastal areas, with their salty air, pose a similar threat, as do urban environments where pollution can introduce a variety of corrosive elements into the air.

The Protective Shield: Custom Air Filters

Custom air filters emerge as a critical line of defense in protecting electronic equipment from these corrosive elements. Unlike standard filters, custom solutions are designed with specific environments and their unique challenges in mind, offering several key advantages:

Targeted Filtration: Custom air filters from UAF can be designed to specifically target and remove the corrosive particles prevalent in an environment, such as salt in coastal areas or industrial pollutants.

Optimized Airflow: Ensuring that electronic components receive adequate ventilation is crucial in preventing moisture buildup, a common catalyst for corrosion. Custom filters achieve this balance, providing effective filtration without compromising on airflow.

Material Selection: The materials used in custom air filters can be chosen for their resistance to corrosion, further protecting the filter’s integrity and ensuring its longevity in harsh environments. Our Quadrafoam™ media is noted for its UV, fungal, and fire resistance, while our OSP filters have passed a 30 day salt fog test using a 5% salt fog concentration per ASTM B 117 in accordance with GR-487 CORE, Issue 5.

Seal and Fit: A perfect seal and fit prevent unfiltered air from bypassing the filter, a common issue in off-the-shelf filters that can lead to exposure of sensitive components to corrosive agents. UAF also offers custom gasket and other accessory solutions to ensure ease of installation with full seal for your equipment.

Emphasizing Prevention

Preventing corrosion before it starts is far more cost-effective than addressing the aftermath. Regular maintenance and replacement of custom air filters are paramount in this preventive approach, ensuring that filtration systems continue to operate at peak efficiency. Additionally, understanding the specific environmental risks associated with an electronic system’s location allows for more informed decisions regarding the necessary filter specifications and materials.

Custom UAF filters can optimize the ambient cooling of your equipment while protecting your critical electronics from corrosion.