Advanced Filtration Solutions for Large Battery Storage Systems

Protecting Battery Energy Storage Systems (BESS) with Custom Air Filtration

As large-scale battery energy storage systems (BESS) become critical components of renewable energy infrastructure, effective thermal management and environmental protection are essential to ensure safe, reliable, and efficient operation. Universal Air Filter (UAF) specializes in air filtration solutions designed for outdoor battery storage enclosures, addressing the unique thermal, environmental, and operational challenges faced by BESS operators.

Thermal Management & Direct Air Cooling Support

Many BESS systems rely on Direct Air Cooling (DAC) as a cost-effective, energy-efficient method for dissipating heat generated by batteries and power electronics. UAF filters are specifically designed to support DAC airflow while filtering out harmful particulates, ensuring the cooling system operates efficiently.

Beyond battery modules, forced air cooling and direct air cooling with filters are also commonly used to protect critical components such as Battery Management Systems (BMS), Inverters, and Converters/Power Conversion Systems (PCS). Filtration helps safeguard these sensitive electronics from particulate buildup that can impair thermal performance and reduce system reliability.

Key Benefits of UAF Filters in DAC Systems

- Open-cell Quadrafoam media balances dust capture with high airflow rates

- Fully customizable filter designs to fit directly into louvers or enclosures

- Available in multiple thicknesses, densities, and mounting options

- Lower cooling system noise and minimize HVAC requirements

Advanced Protection Against Environmental Threats

Outdoor BESS enclosures face constant exposure to environmental hazards, including dust storms, salt fog, heavy rains, and industrial pollutants. UAF’s filtration solutions provide multi-layer protection to extend equipment life and reduce maintenance cycles.

Environmental Safeguards

- Weather Resistant Filters with MERV 11 or MERV 15 pleated media

- Hydrophobic pre-filters that repel moisture and prevent water intrusion

- Corrosion-resistant materials for coastal installations

- Cleanable and washable pre-filters that extend lifespan

Filtration for Non-Direct Air Cooled Systems

In non-direct-air-cooled BESS architectures, filtration remains a critical factor in maintaining thermal performance, protecting components, and supporting long-term system reliability. UAF offers solutions specifically designed to enhance the performance and durability of these systems:

Heat exchangers rely on medium-efficiency filtration to prevent particulate buildup and clogging of heat sink fins, which can lead to system downtime and costly maintenance. Permanent screens are also commonly used to block larger debris, insects, and rodents.

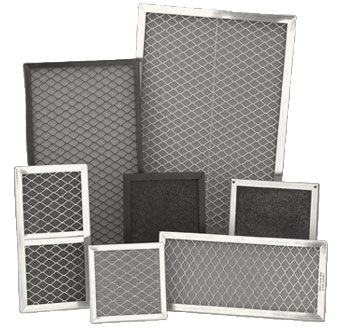

Liquid cooling systems typically incorporate air filters to protect radiators or heat exchangers and maintain consistent cooling efficiency. UAF solutions, including Quadrafoam, Electrostatic media, Polyester filters, Metal Mesh, and Stainless Steel Screens, help extend the life of these critical components.

HVAC units used to cool sealed battery modules often use standard filters that are not designed for the challenging environmental conditions present at many BESS sites. Upgrading to a UAF high-efficiency filter or adding a cleanable pre-filter can simplify ongoing maintenance and help the system sustain optimal performance and energy efficiency.

Enhanced Safety with Fire-Rated Filtration Media

BESS enclosures must account for potential thermal runaway events or internal electrical fires. To support system safety, UAF offers filters made from UL 94 HF-1 rated Quadrafoam, a self-extinguishing material that helps prevent flames from spreading through airflow paths. Custom filter designs maintain airflow while reducing combustible material exposure within the enclosure.

Custom-Engineered Solutions for Every BESS Enclosure

UAF works directly with BESS manufacturers and enclosure designers to deliver air filters fully customized to fit the unique dimensions, mounting needs, and performance requirements of each project.

Custom Options Include:

- Non-square filter shapes to fit complex enclosure designs.

- Integrated mounting features such as drainage holes, thru-holes, PEM fasteners, thumb screws, or gaskets.

- Filter media selection based on environmental conditions, thermal needs, and target IP rating.

Whether integrating into existing louvers or developing a custom mounting strategy, UAF’s engineering team supports rapid prototyping and design collaboration to ensure optimal fit and performance.

Optimized for Regulatory Compliance & Long-Term Reliability

Most BESS enclosures must meet NEMA, IP (Ingress Protection), and UL standards to ensure protection against environmental threats and mechanical failures. While overall enclosure design drives these certifications, UAF filters directly contribute to achieving required IP levels by:

- Enhancing dust and water resistance through proper filter media selection and sealing techniques.

- Supporting IP54, IP55, and IP65 levels even in environments with extreme dust, moisture, or salt exposure.

- Reducing filter replacement frequency and associated maintenance costs through multi-stage, serviceable filter systems.

With proper filtration, operators can reduce unscheduled downtime, protect critical components, and enhance long-term system reliability.

Addressing Common BESS Filtration Challenges

UAF’s experience working with BESS manufacturers has revealed common filtration pitfalls, including:

| Challenge | UAF Solution |

| Inadequate filtration selected early in design, leading to compliance issues | Consulting with UAF during the design phase ensures that filters meet IP and thermal management goals upfront. |

| Heat exchangers lacking filters, requiring costly maintenance to clean heat sink fins. | UAF filters protect heat exchangers from debris buildup, reducing deep cleaning costs. |

| High noise from HVAC systems in residential-adjacent sites. | UAF filters support quieter DAC cooling, lowering noise while maintaining effective cooling. |

By partnering with UAF early, BESS manufacturers can avoid costly retrofits, improve system uptime, and enhance both thermal performance and environmental protection.

Future-Proof Your Battery Storage Infrastructure with UAF

Whether you’re designing a new BESS enclosure or optimizing an existing installation, UAF provides tailored filtration solutions that address your specific thermal management, environmental protection, and regulatory compliance needs. Consult with our engineering team early to streamline your design process and ensure optimal long-term performance.