Quadrafoam™ Air Filters

Protect equipment with fire-resistant, cleanable filters

Quadrafoam™ air filters offer low-pressure drop, fire resistance, hydrolytic stability, and the ability to capture large amounts of airborne dust in industrial enclosure applications. Quadrafoam™ is ideal for use in equipment where permanent, cleanable filters are most appropriate.

Applications

Quadrafoam™ air filters are offered in a broad range of porosities (PPI) to meet custom filtration performance requirements. They also comply with UL 94 HF-1 self-extinguishing flame safety standards for electronics in industrial, medical, telecom, and military electronics air filter applications. Quadrafoam™ air filters are the ultimate solution in networking and communications equipment where compliance to NEBS, ATCA and other industrial computer specifications are required.

More Information

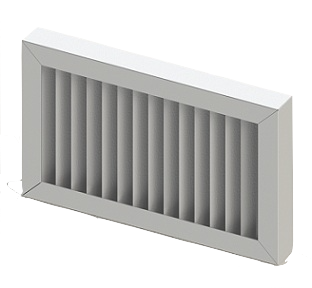

Quadrafoam™ and Quadrafoam II™ filters are ideal for telecom, medical, power gen, military/defense, and many other industrial and commercial products. Quadrafoam™ and Quadrafoam II™ filters are configured in made-to-size aluminum-framed, cleanable filters, or cut-to-size pads, for fresh air intake and exhaust. Quadrafoam™ and Quadrafoam II™ air filters are effective filters for GR-63-CORE and help enclosures meet GR-487-CORE and various MIL-STD, NEMA and IP ratings. Quadrafoam II™ air filters are specially designed for harsh environments and are formulated to better withstand prolonged exposure to high temperature and high humidity environments.

Expanded on our specially designed Uni-Grid equipment, using .040″ thick, 3000 series aluminum. Uni-Grid expanded aluminum is approximately 85% open to maximize air flow. Quadrafoam™ and Quadrafoam II™ filters use Uni-Grid support on one or both sides.

Framed Filters +/- 0.06″ length & width, +/- 0.03″ thickness

Pad Filters +/- 1% (0.06″ min.) length & width, +/- 0.06″ thickness

Quadrafoam™ and Quadrafoam II™ are open cell polyurethane foams specially coated to provide improved flame, fungus, and UV radiation resistance. They feature deep loading, high dust holding capacity, low air flow resistance and mist elimination for use in extremely wide climatic conditions.

Quadrafoam™ filter media is available in all frame models in various pore sizes (10 through 80 PPI Gray and Black).

Quadrafoam II™ filter media is available in all frame models in various pore sizes (10 through 45 PPI Gray and Black).

Model

Quadrafoam™ Media Thickness

Frame Thickness

CAD Tools FF-2X .25

.23

Create 3D CAD FF-3 .25

.30

Create 3D CAD FF-5 .25 or .375

.43

Create 3D CAD FF-5X .375 or .50

.50

Create 3D CAD FF-1025-B .25

.88

Create 3D CAD FF-1050-B .50

.88

Create 3D CAD Window Pane .25, .375 or .50

.19 to 1.00

Create 3D CAD Flex Frame .25, .375 or .50

.062

Create 3D CAD

| UL 900, UL 94 HF-1 | MIL-STD |

| NEBS GR-63-CORE | ATCA |

| NEBS GR-78-CORE | MicroTCA |

| NEMA | CompactPCI |

| IP | FMVSS 302 |

Roll formed into a strong, sturdy one-piece channel, using 3000 series aluminum. Frame is tightly fitted to filter media and fastened with an aluminum rivet. The UL listing, model number and air flow direction are roll imprinted into the frame. Part number is metal stamped into frame for quick, accurate identification.

In addition to the standard roll formed frame design, more custom options are also available. The Windowpane filter design allows for a customized, aluminum “frame-n-pane” design that integrates the frame and a series of crossing, reinforcing intermediates that provide media support. The Flex-Frame filter allows for a customized, flexible polypropylene “frame-n-pane” design that integrates the frame and a series of crossing, reinforcing intermediates that provide media support.

| Model | Quadrafoam™ Media Thickness | Frame Thickness |

|---|---|---|

| FF-2X | .25 | .23 |

| FF-3 | .25 | .30 |

| FF-5 | .25 or .375 | .43 |

| FF-5X | .25, .375 or .50 | .50 |

| FF-1025-B | .25 | .88 |

| FF-1050-B | .50 | .88 |

| Windowpane | .125, .25, .375 or .50 | .19 to 1.00 |

| Flex-Frame | .125, .25, .375 or .50 | .040, .062, .094 |

Quadrafoam™

| Quadrafoam™ Models: FF-2X, FF-3, FF-5, FF-5X, FF-1025-B | ||

| Size | Initial Resistance* (Pascals) |

Average Synthetic Dust Weight Arrestance(%) |

| 10 PPI | 0.01 (2,49) | 38 |

| 25 PPI | 0.05 (12,44) | 66 |

| 45 PPI | 0.07 (17,41) | 80 |

| 60 PPI | 0.12 (29,84) | 82 |

| *in inches water gaugeTests performed according to ASHRAE Standard 52.1 -1992 at 300 feet per minute (1,53 m/s) face velocity. | ||

| Quadrafoam Models: FF-5X, FF-1050B | ||

| Size | Initial Resistance* (Pascals) |

Average Synthetic Dust Weight Arrestance(%) |

| 10 PPI | 0.03 (7,46) | 63 |

| 25 PPI | 0.08 (19,89) | 83 |

| 45 PPI | 0.16 (39,78) | 91 |

| 60 PPI | 0.25 (62,16) | 91 |

| *in inches water gaugeTests performed according to ASHRAE Standard 52.1 -1992 at 300 feet per minute (1,53 m/s) face velocity. | ||

| Quadrafoam Models: FF-2X | ||

| Size | Initial Resistance* (Pascals) |

Average Synthetic Dust Weight Arrestance(%) |

| 45 PPI | 0.04 (9,95) | 65 |

| 80 PPI | 0.18 (29,84) | 81 |

| *in inches water gaugeTests performed according to ASHRAE Standard 52.1 -1992 at 300 feet per minute (1,53 m/s) face velocity. | ||

Quadrafoam II™

| Quadrafoam II™ Models: FF-2X, FF-3, FF-5, FF-5X, FF-1025-B | ||

| Size | Initial Resistance* (Pascals) |

Average Synthetic Dust Weight Arrestance(%) |

| 10 PPI | 0.01 (2,49) | 38 |

| 30 PPI | 0.05 (12,44) | 66 |

| 45 PPI | 0.07 (17,41) | 80 |

| *in inches water gaugeTests performed according to ASHRAE Standard 52.1 -1992 at 300 feet per minute (1,53 m/s) face velocity. | ||

| Quadrafoam II Models: FF-5X, FF-1050B | ||

| Size | Initial Resistance* (Pascals) |

Average Synthetic Dust Weight Arrestance(%) |

| 10 PPI | 0.03 (7,46) | 63 |

| 30 PPI | 0.09 (22,38) | 83 |

| 45 PPI | 0.16 (39,78) | 91 |

| *in inches water gauge

Tests performed according to ASHRAE Standard 52.1 -1992 at 300 feet per minute (1,53 m/s) face velocity. |

||

| Quadrafoam II Models: FF-2X | ||

| Size | Initial Resistance* (Pascals) |

Average Synthetic Dust Weight Arrestance(%) |

| 45 PPI | 0.04 (9,95) | 65 |

| *in inches water gauge

Tests performed according to ASHRAE Standard 52.1 -1992 at 300 feet per minute (1,53 m/s) face velocity. |

||